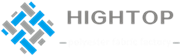

Hightop Woven Filter Belt are made using a variety of materials and are designed to be used in different industries but more so for sewage treatment factories that requires filter belt that has an excellent water and air permeability and is chemical and heat resistant. Due to its unique design structure, it allows sludge to get off filtration, the belt is also easy to maintain and has longer life span.

Applications:

- Coal plants

- Mining tailing disposal

- Sludge dehydration

- Juice squeeze (wine and juice production)

- Water treatment plants

- Ceramics

Benefits:

- Easy maintenance and longer working time

- Acid resistant

- Alkali resistant

- Non-revealed sludge

- Excellent water and air permeability

- Easy maintenance and longer working time

- Acid resistant

- Alkali resistant

- Non-revealed sludge

- Excellent water and air permeability

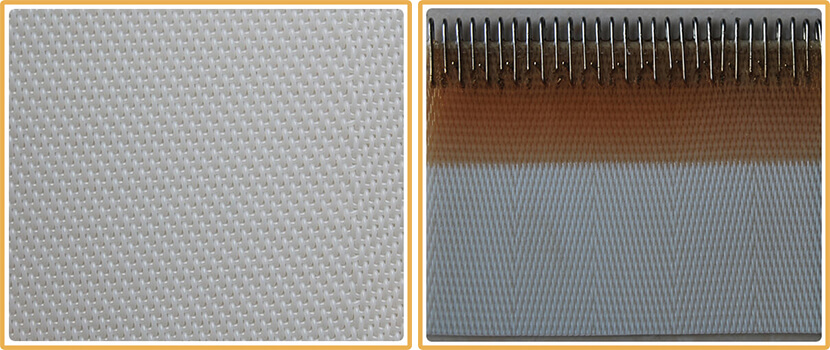

| Model of Fabrics | Wire Diameter (mm) | Density (wire/cm) | Strength (N/cm) | Air Permeability (CFM) | ||

| Warp | Weft | Warp | Weft | Area of Surface | ||

| 16903 | 0.7 | 0.9 | 16.2 | 5.1 | ≥2200 | 494 |

| 22903 | 0.5 | 0.9 | 22.5 | 5.2 | ≥2000 | 425 |

| 26808 | 0.5 | 0.8 | 24.3 | 8 | ≥2100 | 320 |

| 15905 | 0.9 | 0.9 | 15.5 | 5.7 | ≥4500 | 422 |

| 151105 | 0.9 | 1.1 | 15.3 | 4.6 | ≥5000 | 422 |