The papermaking felt is integral in the papermaking process. Hightop papermaking felt undergoes strict quality control to ensure the quality of the paper. Felts are important because of their dewatering ability allowing wet paper to easily be transferred to the forming section without blemishing the paper web.

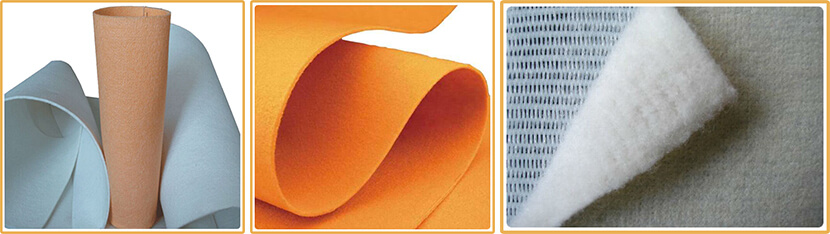

A wide range of felt is used depending on the series type used by the company namely – single layers, double layer and triple layer base mesh. Depending on the layers, felts can be divided into press felt, pick-up felt, forming felt, pulp board and MG felt.

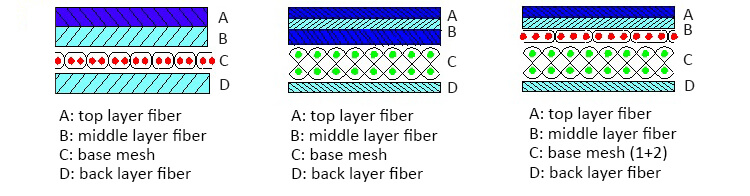

How Papermaking Felts are made:

How Papermaking Felts are made:

The felts are composed of a base mesh layer and fiber layer. The base mesh can be a single, double or triple layer. Aside from this, the double layer can also sometimes have 1+1 laminated. The triple layer on the other hand can be either 1 + 2 or 2+2 laminated. The mesh bases are made up of twisted monofilaments or monofilament yarns whereas the fiber layers are composed of different polyamide fibers. The two bases are attached via needle stitching to form the felt.