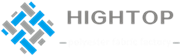

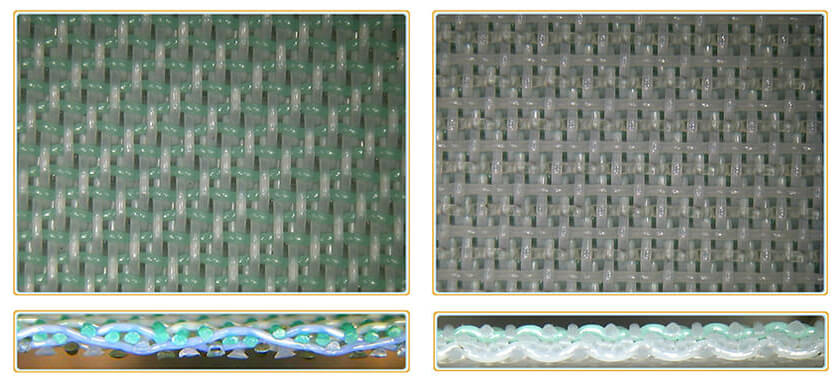

The Double Layer forming fabric is ideal for companies who are looking for more stability than what the single layer can provide. The Double layer has higher warp and weft density making it more stable than the single layer. That said the Double layer is less stretchable.

In order to improve fabric life, wire mark and flatness of the product, one can choose the material type as well as the diameter of the sheet side and side wefts. The Double layer also has an excellent drainage force, which helps retention, reduces lint and improves the paper layer.

Example of Products:

Example of Products:

- Printing paper

- Board grade

- Onion skin paper

- Wrapping paper

| Model of Fabrics | Wire Diameter (mm) | Density (wire/cm) | Strength (N/cm) | Air Permeability (CFM) | |||

| Warp | Weft | Warp | Weft | Breaking | Joint | ||

| 60188 | 0.17 | 0.18/0.20 | 68 | 47 | ≥900 | ≥650 | 388 |