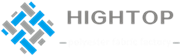

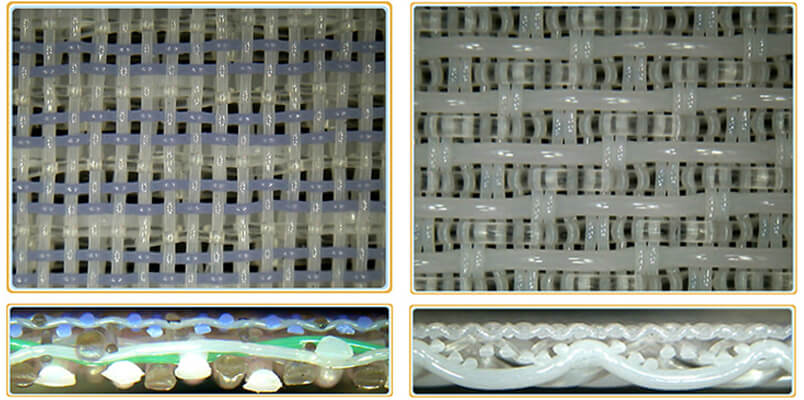

Choosing the right type of forming fabric is important to the integrity of the product. The Triple layer Forming fabric is the best for those who wants to retain as much fiber and faster drainage as possible. The increase with the count of the yarn ensures better support and retention while at the same time reduces the wire marks. Due to its excellent stability and resistant, it is ideal for high-speed paper machine.

Example of Application:

Example of Application:

- Board grades

- Wrapping paper

- Newsprints

- Tissue

- Printing paper

| Model of Fabrics | Wire Diameter (mm) | Density (wire/cm) | Strength (N/cm) | Air Permeability (CFM) | |||

| Warp | Weft | Warp | Weft | Breaking | Joint | ||

| 564020 | 0.13, 0.21 | 0.17, 0.17/0.40 | 56 | 59 | ≥1100 | ≥700 | 316 |

| 364520 | 0.18, 0.27 | 0.18, 0.17/0.45 | 42 | 50 | ≥1100 | ≥700 | 348 |

| 365020 | 0.18, 0.27 | 0.20, 0.20/0.50 | 42 | 43 | ≥1100 | ≥700 | 449 |

| 5630SSB -32 | 0.13, 0.21 | 0.13, 0.13/0.30 | 60 | 65 | ≥1000 | ≥600 | 316 |

| 5635DB10 -32 | 0.13, 0.21 | 0.15, 0.15/0.35 | 58 | 64 | ≥1100 | ≥700 | 335 |